Production line of semi-automatic pulp molding egg tray equipment

Date:2019/11/22 16:15:45 Browse times:

Product model: ZB1000

Application: it can produce large-scale work package products. When the height of the product exceeds 10 cm, it can be used. Output: 900-1200 pieces / hour

Process customization: special mold needs customization

Product introduction:

Hebei Haichuan pulp molding manufacturing Co., Ltd., established in 1998, is located in Gaocheng Zhangjiazhuang industrial zone. It is a product import and export business company focusing on egg tray equipment and pulp molding equipment, research and development, production and sales. We have established cooperative relationship with more than ten companies in the industry, because of the strong support of cooperative manufacturers, we can serve customers more perfectly.

After more than 20 years of development, our company has learned from others' strong points and accumulated a number of patents! Modern production equipment and strong R & D capacity make Haichuan always in an important position in the industry, and Haichuan users have been all over the country! The company's service concept: to provide scientific and professional supply scheme, let customers choose mechanical equipment more simple and more suitable, and provide complete Fine technical consultation and training can make customers use more correctly and efficiently, provide perfect and reliable transformation and recycling scheme, let customers use the equipment, and obtain higher and more product value! Hebei Haichuan, Haina Baichuan, let us join hands with our respected customers to create a better tomorrow!

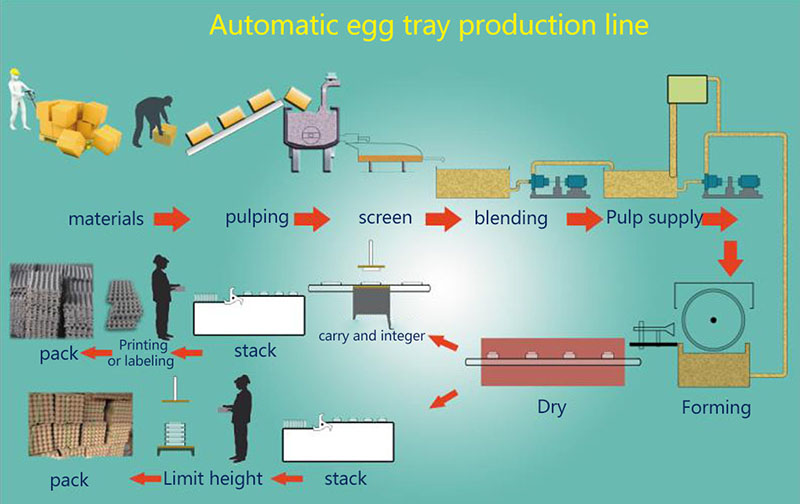

Technological process

Introduction of equipment

The pulp molding equipment we can provide can be divided into 800-1200 pieces per hour, 2000-3000 pieces per hour, 3000-4000 pieces per hour, 4000-6000 pieces per hour and 7000 pieces per hour according to the output size, which can meet the needs of various customers.

Successful case

1. Overseas Chinese in South Africa are required to produce 8000-10000 pieces / hour of equipment and a variety of pulp molding products at the same time, so as to finally meet the customer's demand and customize the z8000 type roll and egg carrier machinery.

2. Xinjiang market is the largest market in China, with a high demand. Customers from Xinjiang have customized a new type of zj5000-8m5 egg carrier with an output of 6000 pieces / hour.

3. Customers from South Africa have high requirements for equipment automation. They want to produce a variety of pulp molding products at the same time, and finally order d1000 intelligent control small egg tray equipment in our company.

4. Egyptian customers come to our company to inspect the new egg tray equipment, with the output of 5000 pieces / hour, and the latest multi-layer drying technology. The final customer chooses zj5000-8 multi-layer steel structure drying egg tray machine

5. Indian customers have visited our factory for many times and are very satisfied with the civil engineering drying technology of our company's patented technology. Finally, zg4000-8 type egg holder equipment for civil engineering drying was selected.

6. In February 2019, Iranian customers accompanied the translator to visit our factory, and went to our production line to understand the process and visit the production line. Finally, the customer selected zj5000-8m5, and the customer paid a deposit on the spot to show sincerity.

7. In October 2019, the old Indonesian customers came to our factory for a visit. The customers used to buy our small equipment, which was dried in the way of airing. Because Indonesia belongs to the archipelago country, the air humidity is high, and the rainy season is long, so the production can not keep up with it. After the actual visit to our production line, they were very satisfied, and finally bought our z2000-4m4 equipment.

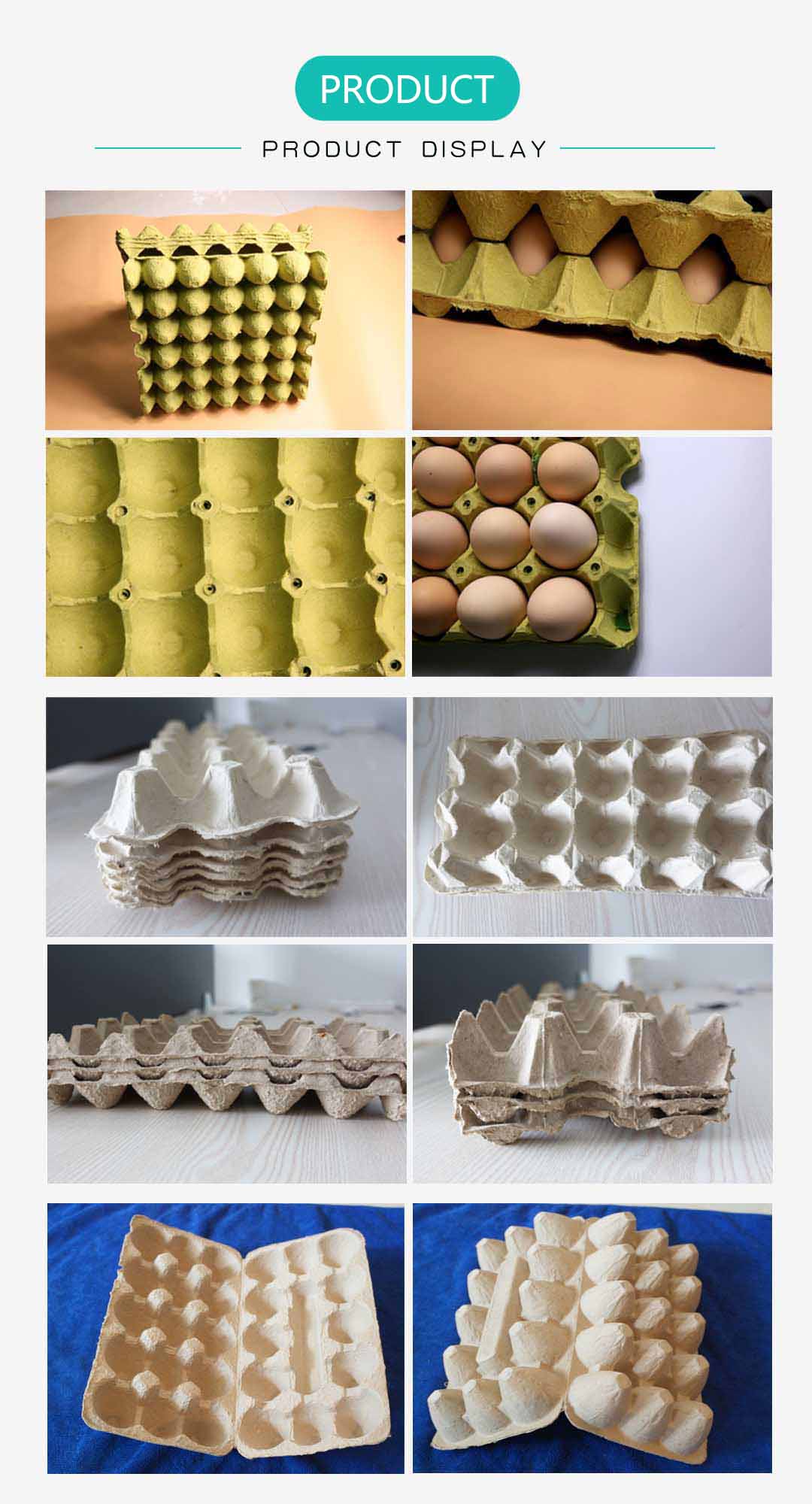

Final product

Equipment superiority

Product advantages:

1. Imported transmission, long service life and stable operation

2. Seal the dehydrated parts with 304 stainless steel and mechanical seal. The equipment is more wear-resistant, not prone to aging, air leakage, etc.

3. The traditional mechanical principle is used for the operation and positioning of the equipment, which is error free and not prone to failure, so as to overcome the disadvantages of electrical control

4. The drying kiln technology has its own patents and intellectual property rights, which is about 20% more energy-saving than the same industry

5. Large diameter stick bearing is adopted for the water tank of the main engine, which is stable in operation and long in service life

Description:

1. The size of the egg tray is generally 30 * 30cm, and the weight of the finished egg tray is 80-100g.

2. The labor demand is generally as follows: 1 for pulping, 1 for molding, 2 for packing and 1 for warehouse. (excluding the drying part)

3. Floor area: generally 1000 ㎡ for air drying and 200 ㎡ for equipment.

4. If it is a civil dry road, the land occupation of the equipment is 50-80m * 5m * 3-3.5m

5. If it is a steel structure drying trunk road, the land occupation of the equipment is 30m * 15m * 4m. The recommended workshop is 50m * 15m * 4m

6. We provide 1-2 engineers with installation guidance until the customer can operate alone.

7. Warranty period: 1 year for the whole machine and 5 years for main parts.

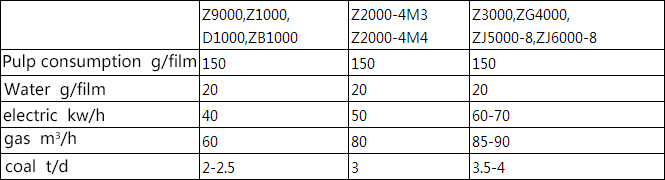

Production consumption: